Steel Castings Pty Ltd of Derham and Bertie Streets

by Jim West and David Radcliffe

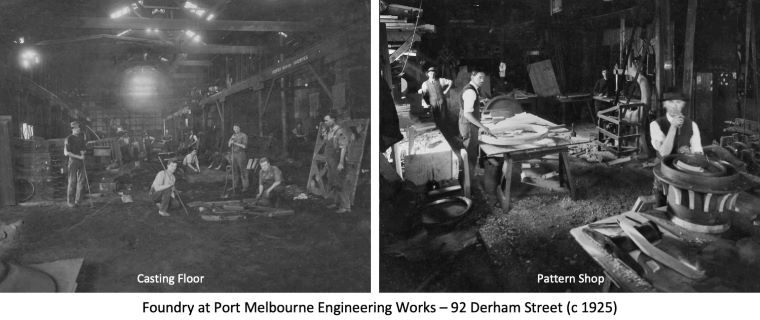

The premises of the Port Melbourne Engineering Works, built by Albert T Harman in Derham Street, Port Melbourne in 1902, included a foundry for casting components out of iron and brass.[1] In November 1934, this foundry was purchased by his son, Alfred Henry Harman, and James Robertson and registered as JV Robertson Pty Ltd.

Early in the Second World War, JV Robertson Pty Ltd recognized the need for components cast out of steel (rather than iron or brass) for use in defence equipment. So Norman Hosking, a metallurgist, joined JV Robertson Pty Ltd as a shareholder in April 1942, and the company installed a Tropenas converter and began manufacturing steel castings. Correspondingly, the production of brass and iron castings was gradually wound back. Also in 1942, the Victorian Department of Forests and Lands granted JV Robertson Pty Ltd an annual licence to occupy 2.5 acres of reclaimed land at 49 Bertie St. Port Melbourne. To better reflect its new business direction, on March 15, 1943, the company changed its name to Steel Castings Pty Ltd.[2] The original 15 cwt. (762 kgs) converter was later upgraded to a 22 cwt. (1,118 kgs) unit, which was fed with molten iron from a 36” (0.914 meter) diameter cupola.

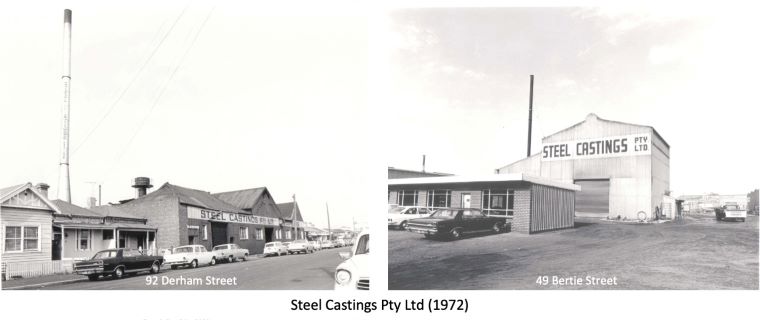

During the post-war reconstruction, the company made steel castings for many clients including the Victorian Railways and Malcolm Moore Industries whose large crane manufacturing plant was in Bertie Street. By 1955, the company was owned by Bruce Harman, son of Alfred Henry Harman, together with Norman Hosking, and some other family shareholdings. Bruce Harman was the managing director. In May 1964, approval was given to build a new main office block and a heat treatment shop at 49 Bertie Street. These were built later that year. Moulding and casting were conducted at Derham St, while the castings were heat treated and dressed at Bertie St. Staff levels continued to rise, and in the early 1970’s exceeded 50 employees.

However, the nuisance caused by having a foundry located in a suburban street began to catch up with the Derham St facility. As early as the 1940s, the company had attempted to reduce the problems of smoke and dust for nearby homes, not helped by the chimney that was intended to be 120 ft tall being reduced to 80 ft by the government.[3] In 1956, the company was fined for emitting dense yellow smoke for more than the maximum of 6 minutes per hour allowed, believed to be the first prosecution under the Smoke Regulations of 1936.[4]

The story is told that on days when they cast metal, the first task was to check which way the wind was blowing to determine from which streets they would get complaints, especially on washing day. In addition to smoke and noise impacting the neighbours, on one occasion the 200 kg conical top on the cupola blew off and landed near Woodruff’s Dairy in Bridge Street about 150 m away. Fortunately, no one was injured. The headline is reported to have read, “Flying Saucer hits Port Melbourne”.[5]

Changing community attitudes to pollution and the growing influence of the Environmental Protection Agency sealed the fate of the foundry. In 1972, operations were moved entirely to Bertie Street, where the land was zoned industrial and the company had obtained a 30-year Crown Lease. The Derham St property was purchased by the Port Melbourne Council in September 1972. The new Bertie St foundry and amenities buildings were built in the first half of 1973, including two clean melting induction furnaces, each of 3,000 pounds (1,361 kgs) capacity.

Following a period of steady growth, the 1981 recession had a severe impact. Steel Castings was reduced to 28 employees, and, with only limited funds available, the company could not invest in new equipment and technology. By 1986, the shareholders saw no option other than to sell the business or to close it. Jim West and Alan Soutar, former members of the management team of Vickers Ruwolt which closed its casting operations in Victoria St. Richmond in 1984/5, put together a consortium which purchased Steel Castings on August 1, 1986. Enhanced technological skills saw the reject levels drop from 14% to below 5%. Whereas the largest single casting had been just over 1,000 kgs, by 1987 this had risen to 2,300 kgs and stainless steel castings were now being produced.

In April 1988, two smaller high-frequency furnaces were purchased from Hawker de Havilland out of the recently closed Commonwealth Aircraft Corporation foundry in Lorimer Street, Fishermans Bend. By June 1988, the company was debt free and trading profitably. Later that year, Steel Castings was contracted by the WA State Government to manage the winding up of the State Engineering Works in Fremantle which had produced the famous “winged keel” which enabled Australia II to win the America’s Cup.

During the 1990s, large pump and valve castings for the offshore oil & gas and petrochemical industries became Steel Castings largest markets, which required an exacting combination of very high quality, on-time delivery, and international competitiveness. Other products included beater webs for the Yallourn and Loy Yang A&B Power Stations, line-shaft bearings for the FFG Frigates built at Williamstown, pinion gears for sugar mills in Queensland and Fiji, communication domes for the Collins class submarines built in Adelaide, non-magnetic propulsion castings for the RAN minehunters built in Newcastle, mooring castings for BHP Petroleum, and trackpads for large earthmoving equipment. The maximum ingot size was now 600 mm square, with each ingot weighing 5.25 tonnes.

The new millennium saw the Steel Castings’ Quality Management System approved from Lloyds Register of Shipping, Kvaerner and LRQA. Significant castings delivered were Pelton wheels for the Rubicon power station and stainless-steel valves weighing nearly 5 tonnes for Woodside’s LNG Train 4. But clouds were forming on the horizon. The potential of Fishermans Bend as a place for future urban development meant that the land tax on the Bertie Street property trebled in the period 2001 to 2003. Consequently, on March 26, 2004, Steel Castings announced it would close. All the plant, equipment and intellectual property was sold to Davies and Baird Pty Ltd in Coburg and new jobs were found for all the employees.[6] The last metal was poured at Bertie St on May 7, 2004. A century of casting metal in Port Melbourne initiated by Alfred T Harman, had come to an end.

[1] Casting is the process of pouring molten metal into a mould to form a metal component of a specified shape.

[2] During the First World War, a former blacksmith shop at 202 Bay St was operated as a foundry by a company called Steel Castings Pty Ltd. The foundry which made parts for bicycles and motor cars closed in 1918. There is no connection between this firm and the later Steel Castings Pty Ltd.

[3] ‘Firm unable to reduce smoke nuisance’, Record (Emerald Hill), 27 May 1944, p. 2. http://nla.gov.au/nla.news-article165035363.

[4] ‘Where there is smoke…’, Argus (Melbourne), 7 September 1956, p. 8. https://trove.nla.gov.au/newspaper/article/84385307.

[5] ‘Grimwade Castings’, Peter Griffin, PMHPS Meeting Presentation, 24 October 2005.

[6] In 2011, Davies & Baird was acquired by Flowserve. It was merged into Quality Castings in 2013 and became part of Beckwith Iron and Steel in 2015.

3 Comments

Glenn McCabe

My father had the contract to mow the nature strips of steel castings from the 70’s until his passing. i then took on to the mowing until the company closed.

David Radcliffe

Hi Glenn

Always great to hear the personal connections that readers have with the people and places in stories we write. Thanks. David

Russell Eadie

I worked for steel Castings in the 80s on 2 occasions, during the Hoskings ownership and when Jim West and Alan Soutar were the bosses, great blokes. My family also did the abrasive grit blasting of the castings in Alfred street Montague. Long time ago when the Port was working class and a great place to live.