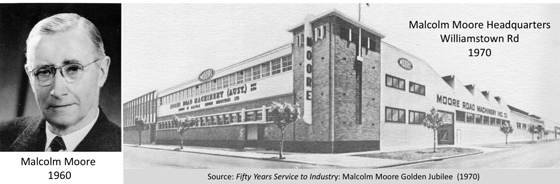

Malcolm Moore and Albert Longoni

by David Radcliffe

Over the past four years, the article on Malcolm Moore Pty Ltd has elicited many reminiscences from people with personal or family ties to this former Port Melbourne based engineering company. The numerous fond memories suggest it was a great place to work, one that fostered loyal employees. Most of these responses are based on experiences from the 1960s until 1980s, when Malcolm Moore was bought out.

The foundations for the long term success of the company were laid in large part by the contributions of two engineering innovators, Malcolm Moore and Albert Longoni. Moore had a strong business sense with an eye for improving existing equipment and a passion for production efficiency while Longoni was an early adopter of new fabrication techniques who brought the European approach to engineering design and was adept at commissioning complex engineering facilities. They came from contrasting backgrounds.

Malcolm Stewart Moore was born in Brisbane in 1888. His father was an ironmonger who worked for the Brisbane branch of the machinery importer and distributor founded in Melbourne by his father-in-law, Alfred Shaw & Co. The Moore family became insolvent in 1897 when the firm went bust. They moved to Melbourne around 1902 and settled in Elsternwick. Moore finished his schooling at Caufield Grammar and graduated from the University of Melbourne in mining engineering (1911) and civil engineering (1912). As a newly graduated assistant engineer on the construction of the Bairnsdale to Orbost line, he introduced more efficient and cost effective methods of excavation using a grab-bucket he designed. He was also commended for other innovative construction methods he introduced.[1]

Moore worked in Britain during the First World War. In 1915-16, he was the assistant general manager of the National Projectile Factories in Glasgow where he experienced what it took to stand up a new manufacturing facility within tight deadlines and to train up a new workforce, mostly women, in relatively sophisticated production methods. Subsequently he was the director of the National Ordnance Factories Section, London. In 1916, his brother John Heywood Moore was killed in action in France. Moore sailed back to Australia in 1919 and lived with his parents at Shepparton where his father was now an orchardist.

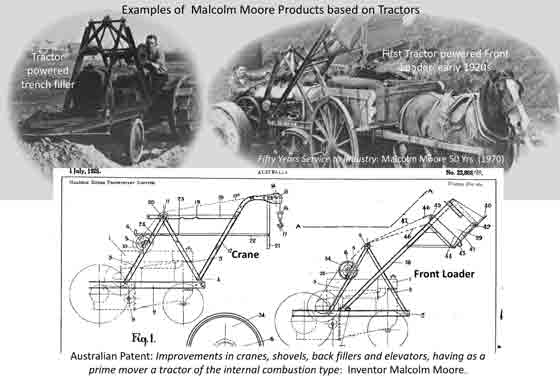

In 1920, Moore started his own business as a consulting engineer but also acted as an agent for engineering equipment, notably the patented Multi-mix concrete mixer. A year later he was awarded his first Australian patent, for improvements in grab-bucket and a new crane designed by Moore and manufactured by Austral Otis Engineering of South Melbourne, which featured this so-called “Malcolm” grab bucket.

In October 1921, Malcolm Moore Pty Ltd, offering civil and mechanical engineering services, was registered with a capital of £10,000. The offices were in Queen Street and the three directors of this private company were Malcolm Moore, Theodore Lloyd and Donald Baxter. In the first few years, the new company won numerous tenders including those to deliver equipment to Victorian Railways and the Electricity Commission for handling concrete, coal crushing plant suitable for brown coal to the Electricity Commission and electric hoists for the Sydney Harbour Trust.

Moore also established the Tractor Appliance Company Ltd (or TACL), which sold farming implements and was the distributor for Fordson tractors in Victoria. Between 1923 and 1927, he was granted seventeen Australian patents, thirteen of which involved improvements to tractors including their conversion into mobile cranes, elevators, excavators, saw benches, road rollers, and even small locomotives. He would continue to innovate and patent his ideas throughout his career.

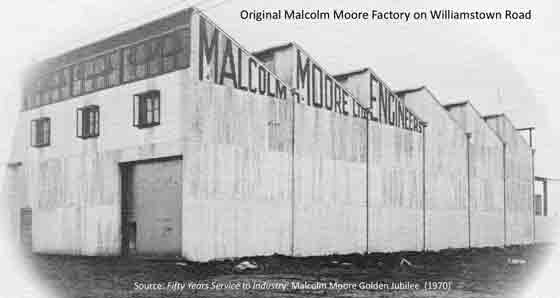

With orders growing, in March 1927, the company went public becoming Malcolm Moore Ltd. The new firm incorporated TACL and the £50,000 in capital they raised helped fund the construction of the galvanized iron shed on Williamstown Road (where Bunnings now stands), the first in what would become a major manufacturing complex.

Alberto Joseph Longoni was born in 1889 in Herisau, in the German speaking area of Switzerland. His grandfather and uncle were contractors who mainly built roads, while his father owned a quarry that provided sandstone for construction projects. Longoni studied engineering at the Federal Technical University in Zurich. During this time he undertook compulsory military service in the Swiss cavalry. While at university he heard stories of Australia from a fellow student so, shortly after graduating in March 1914, he sailed for Sydney. With the start of the First World War just months away, his timing was unfortunate. As an alien he was required to register and then report each time he changed address.

Over the next six years, he worked as a design and construction engineer on a number of large projects; first the Kandos Cement and Lime plant near Mudgee in NSW, and then as engineer-in-chief building the Queensland Cement and Lime plant at Darra, near Brisbane. Subsequently he investigated a lime deposit in WA for a South Australian syndicate and then worked on refurbishment of the smelters at Port Pirie. In late 1919, Longoni moved to Melbourne and set himself up as a consulting engineer, providing professional services in civil and mechanical engineering focused on design. Given the uncertainties he faced with getting work during the war years, he became a naturalised Australian in 1920.

He was the engineer-in-chief for design and construction of the Portland Cement Plant on Maria Island, Tasmania from 1920-1922. He then returned to consulting and his first association with Port Melbourne came in 1924 when he provided a favourable technical report as part of the prospectus to float a company to expand the factory in Ingles Street manufacturing Cindcrete bricks. This unique building product was a defining feature of the semi-detached ‘Bank Houses’ built in Garden City.

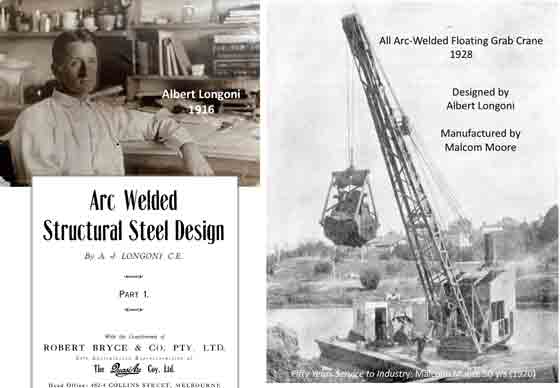

During this period, the trajectory of Longoni’s career changed as he began to pioneer the design of arc-welded steel structures for mechanical applications. This work was done in close association with Quasi-Arc, the British electric-welding equipment supplier, its local distributor, Robert Bryce & Co, and Harry Grove, who headed the construction department at the Metropolitan Gas Company. Longoni went on to develop technical information on welded structures and practical advice for design engineers. This was the era when most iron and steel structures were fabricated using rivets or bolted joints.

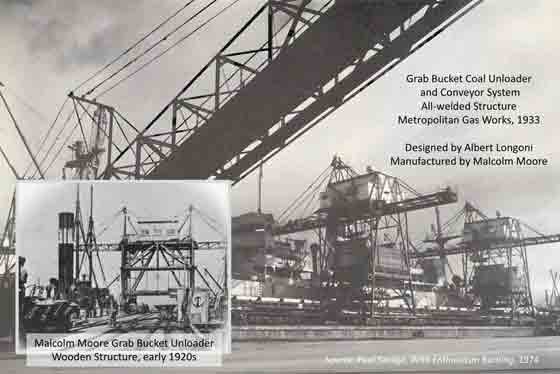

Moore and Longoni first joined forces in the mid-1920s. Longoni designed a variety of pieces of plant and equipment that were manufactured by Malcom Moore. These included trucks and a truck tipping station for Geelong Cement Company and grab transporters for the Footscray Gas Works and Newport Power Station. However, the full potential of their partnership was realised in 1932 when the company won the tender, against leading British competitors, to design and construct a state-of-the-art coal handling facility at the West Melbourne plant of the Metropolitan Gas Company. The pair of loaders at the heart of the system were reputed to be the largest all-welded cranes in the world at the time.

From early in his career, Moore had designed and built many grab-bucket cranes and small conveyor systems. The addition of Longoni’s experience with designing, building and commissioning large cement plants plus his expertise with welded structures made this a world class team.

With true engineering nonchalance, Mr A. J. Longoni, supervising engineer for Malcolm Moore Ltd., who installed the plant blew a little whistle at North Wharf yesterday and set in motion the new mechanical coal-handling machinery of the Metropolitan Gas Co. As 40 tons of coal were lifted by the grab and belt-conveyed to the West Melbourne Gasworks, to the delight of 160 engineers and gas experts, Mr Longoni told me this was not the first time he had watched such a performance, for my job is to get things moving in just this way.[2]

This project cemented the reputation of Malcolm Moore and led to orders for similar coal handling systems elsewhere in Australia. Longoni continued to provide design services as a consultant to Malcolm Moore before finally joining the company in 1936 as a Director and became Chief Engineer. Malcolm Moore was one of many large local firms that advertised in the souvenir program for the Centenary of Port Melbourne in 1939. During the Second World War, the company provided overhead cranes and related equipment to aid in munitions production as well as road making and earth moving for the army. Moore was consultant to the government and a member of the Australian Army Mechanisation Board.

In 1946, Malcolm Moore underwent a major restructuring with the holding company, Malcolm Moore Industries Ltd., being created to oversee five distinct operating divisions based on product types; cranes, conveyors, earthmoving, farm machinery and hydraulics. In the early 1950s, Moore stepped away from the roles of Managing Director and Chairman to pursue his passions for industrial management education and his longstanding work with the Royal Flying Doctor Service. Albert Longoni remained active at Malcom Moore overseeing major coal handling projects until his untimely death in 1954. An era had ended.

If you have stories to share on working for Malcom Moore, please post them here. If you want to comment on this story, please do so below.

Acknowledgement: We thank the grandchildren of Albert Longoni who made available many of his documents and photographs.

David Radcliffe spoke about Malcolm Moore and Albert Longoni at our meeting in October 2020. You can view his presentation here.

[1] Catching the Train to Orbost: Engineering Heritage Australia, Vol 1 No 5, Dec 2014, p18.

12 Comments

Anne Scambary

Great article!

David Radcliffe

Glad you enjoyed it!

Peter Eisenhut

Great article David, thank you. My forebears came from Herisau and and were contemporaries of Longoni. I spent a lot of my childhood there. Malcolm Moore was certainly a household name in Melbourne when I first arrived here, now I have a background story as well.

David Radcliffe

Hi Peter. Thank you for your kind response. Very pleased that the story and video talk have filled in some of the background for you. Did your family have direct connections / associations with the Longoni family in Herisau? David

Peter Eisenhut

Hi David, I have no idea whether or not they even knew each other, but my paternal grandmother was born in Herisau in the same year as Longoni, both my grandfathers were well known businessmen in the textile and banking industries in the town, so maybe their paths crossed – who knows. I remember a railway track maintenance company by that name being based in Herisau, but they may not exist today. kind regards, Peter

David Radcliffe

Hi Peter, As you say we will probably never know if the two families knew each other or interacted. David

Pierre Erol GIRAUDY

Hello,

See my post.

https://www.erolgiraudy.eu/search/label/LONGONI

Pierre Erol GIRAUDY

Giraudy

My Grandmother is a Longoni from Herisau. I remember the family talking about Albert and all the Longoni. I do some genealogy on my tree. I do have many photos.

Pierre Erol GIRAUDY

David Radcliffe

Hello Pierre,

Thank you for sharing the link to your family history blog – some fascinating pictures of the various family members and especially those related to Nice.

In case it is of interest, I wrote a longer version of the Longoni and Moore story for the Engineering Heritage Australia magazine. Here is the link (see pp. 23-30)

https://www.engineersaustralia.org.au/sites/default/files/Learned%20Society/EHA_Magazine_Vol3_No7_January_2021.pdf

David Radcliffe

Pierre Erol GIRAUDY

Hello,

Thanks for this link I read it asap.

EROL

Gary Hunt

Hi David, I watched and thoroughly enjoyed your video on YouTube and have read the article linked above at Engineers Australia.

Moore assisted Tasmanian born Edwin Bentick in setting up a company called Power Plant Pty Ltd in Adelaide in 1935. Also assisting was William Queale, founder of Kelvinator Australia Limited.

Bentick was also associated with S Haunstrup who was the company that engineered silos for grain storage.

I am trying to identify whether South Australia’s first mechanised grain ship loaders were built by either Moore and/or Power Plant. Have you explored Moore’s endeavours in South Australia at all?

I am also curious to know more about Moore’s port projects for loading coal – was their project in Gladstone the only one they did?

Many thanks, Gary

David Radcliffe

Hi Gary

Glad to hear you enjoyed the video.

I do not have any information about Malcolm Moore relating to Edwin Bentick, Power Plant Pty Ltd or a mechanised grain loader in SA. Sorry.

The Malcolm Moore crane and conveyor loading systems I am aware of were for non-organic bulk materials handling applications – coal, minerals, tailings and suchlike. Next week, I will check a MM catalogue in the Society’s rooms to see if there is anything on grain applications and let you know. The catalogue is not comprehensive, so it may not resolve the issue.

best

David Radcliffe